The recycled carbon fibre (rCF) yarns are produced using a classic textile spinning process.

A modified card and machines adapted to the electrically conductive carbon fibres are used.

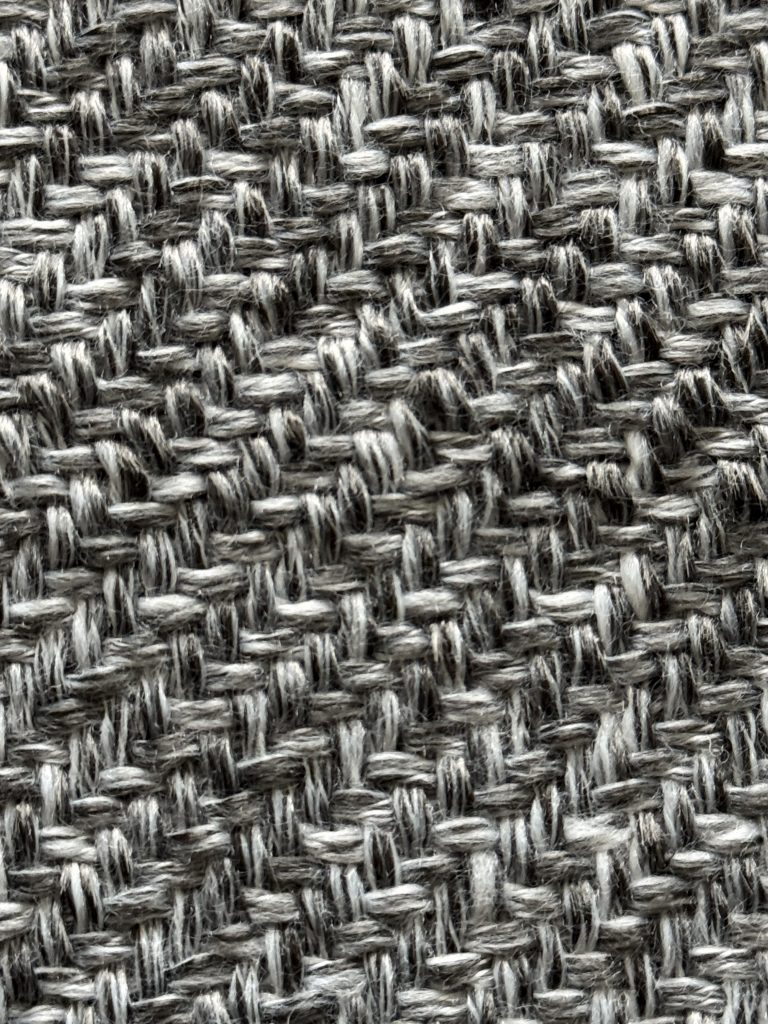

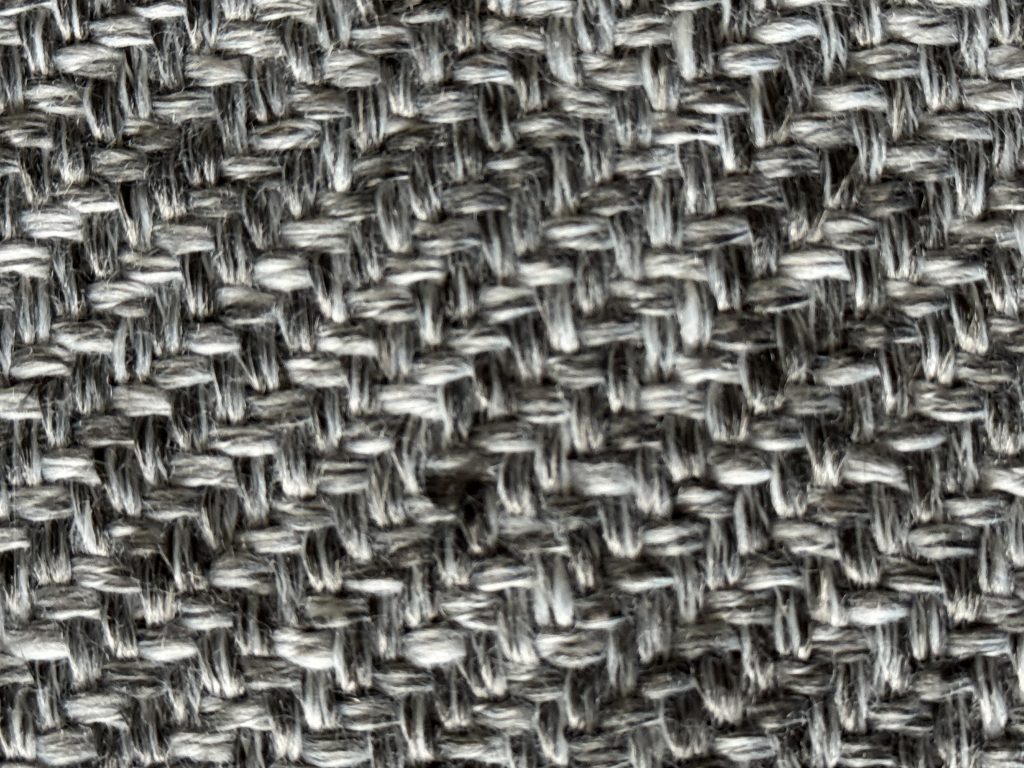

The yarns are made from approximately 80 mm long carbon fibres that lie parallel to each other and are held together by a wrapping filament. The parallel arrangement of the carbon fibres ensures optimum load absorption in the longitudinal direction in the finished component and therefore the highest performance utilisation of the carbon fibre.

The yarns have an elongation and are therefore able to compensate for the forces that occur during the further processing.

The drapability of topographical structures in the component is particularly high.

The yarns can be homogeneously mixed with carbon and thermoplastic fibres (matrix fibres), e.g. carbon or polyamide. This means that a thermoplastic fibre is used directly next to a carbon fibre, which evenly bonds and joins the carbon fibres together in the finished component.

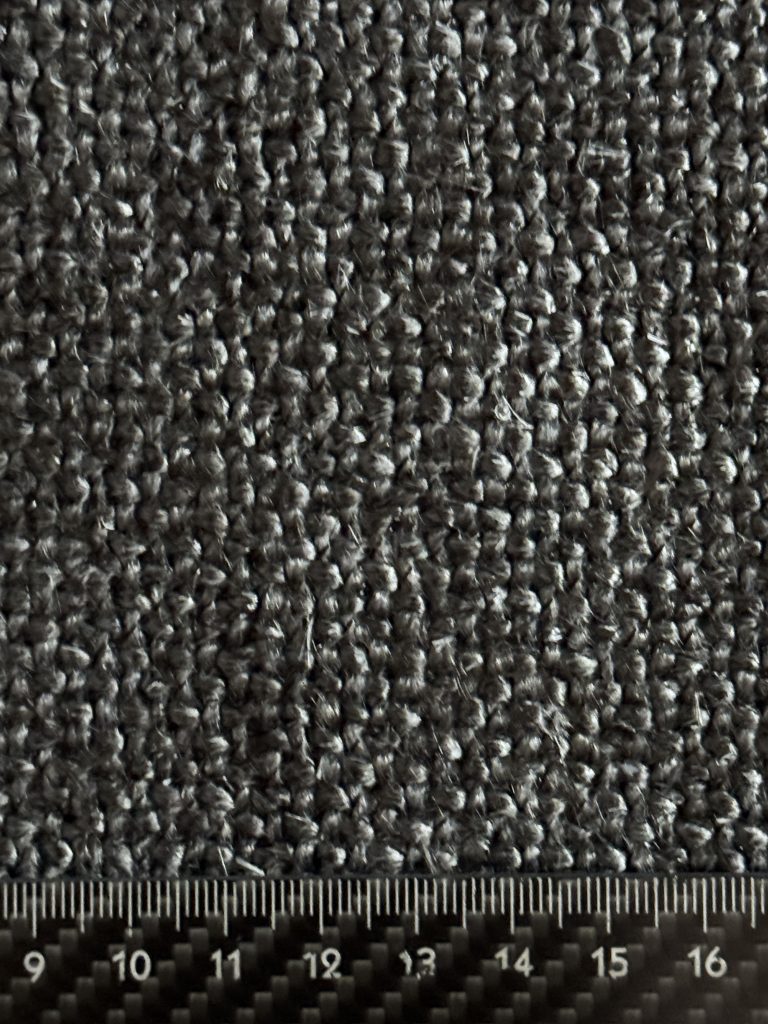

Due to their hairy structure and relatively open structure, staple fibre yarns have a large surface area, which is ideal for resinification in thermosets.

This ensures that the yarn body is saturated and offers great potential for the substance utilisation of the carbon fibre.

The yarns for the thermoplastic process are made from homogeneous, intimate fibre mixtures of carbon and thermoplastic fibres (matrix). This means that the ‘adhesive’ lies directly next to the carbon fibre and can optimally bond the carbon fibres together during the tempering process. The mixtures can be customised to meet individual requirements. Both the mixing ratio and the matrix fibre can be varied and selected according to requirements.

Up to 75% of the strength of original carbon fibres can be achieved with the recycled carbon fibre in the consolidated composite.

The wrapping filament holds the almost parallel aligned carbon fibres together. The material can also be adapted to the further processing process. Stretchable filaments can be used, which enable the staple fibre yarn to be optimally draped in the component. A high-strength glass filament can also be used, which holds the carbon fibres together in a temperature-resistant manner during high-temperature processes.

The yarn count of the thread is generally specified in tex (= gram / 1000m). Gauges from 300 to 1000 tex are currently possible. If coarser yarns are required, it is also possible to twist 2 or 3 threads.

Recycled carbon fibres from rovings are used, which are, for example, overlaid or come from residual spools with a short run length. The fibres are cut into approx. 80 mm long fibre sections. Fibres from torn, dry fabrics can also be used. Fibres from uncritically solvolysed carbon components can also be processed. Pyrolysed fibres with appropriate sizing can also be spun.

The recycled carbon fibres must pass through the individual production steps with particular care. Although the carbon fibre has a high longitudinal strength, it has a low transverse strength. This must be taken into account when processing the high-performance fibres and compensated for by using correspondingly gentle machine settings and machine adjustments.

The fibres are loosened up in a gentle process and homogeneously mixed together. This is a particularly important process for thermoplastic applications.

The card ensures the parallel alignment of the fibres on rollers fitted with fine teeth (= card clothing) in a kind of combing process. Short fibres produced during the recycling process are also removed. This fibre waste can amount to up to 20% of the fibre quantity used. This carding process is particularly demanding for the carbon fibres. A protective sizing on the fibre is absolutely essential to ensure gentle processing of the transversely weak carbon fibres.

Several slivers from the card are presented to the draw frame and drawn together simultaneously to form a sliver. This helps to equalise mass fluctuations and creates a uniform pattern for the spinning process.

The draw frame sliver is fed to a spindle on the spinning machine. In the drafting system, the sliver is drawn again to the desired yarn count. Numerous scientific studies have shown that the wrap spinning process is the most suitable spinning process for carbon fibre. After the drawing process, the fibres pass through a hollow spindle and are wound around by a filament. The filament ties the carbon fibres together to form the yarn, which is wound directly onto a bobbin.

The spun yarn is wound round again and checked for faults by a cleaner. If a fault is detected in the form of a thick or thin section, this section of yarn is cut out and only the good yarn ends are joined together.

Carbon fibre is an expensive fibre due to the high amount of energy used in its production and recycling is therefore an important contribution to sustainability. Like the original fibre, the recycled fibre has the following advantages, among others:

Carbon fibre offers exceptional tensile strength and stiffness compared to its weight. This makes it ideal for applications where high mechanical loads occur.

Carbon fibre is extremely light, which makes it a preferred material in aerospace, automotive and other areas where weight reduction is crucial.

Carbon fibre is resistant to corrosion and chemical attack, which extends its service life and reduces maintenance costs.

Carbon fibre retains its mechanical properties at high temperatures, making it suitable for applications in extreme environments.

Carbon fibre is electrically conductive, which makes it suitable for applications in electronics and electromagnetic shielding.

Carbon fibre can be moulded into different shapes and structures, giving designers and engineers great flexibility when designing components.

Carbon fibre has excellent vibration damping properties, making it ideal for applications where vibrations and noise need to be reduced.

The use of recycled carbon reduces the CO2 footprint by up to 84% compared to the original product. It is therefore worth collecting the waste from production with virgin fibre by type and then reusing it for an alternative product in yarn production.

The carbon footprint of recycled carbon fibre is an important issue, especially in the context of sustainability and environmental protection. Here are some aspects that influence the carbon footprint of recycled carbon fibre: